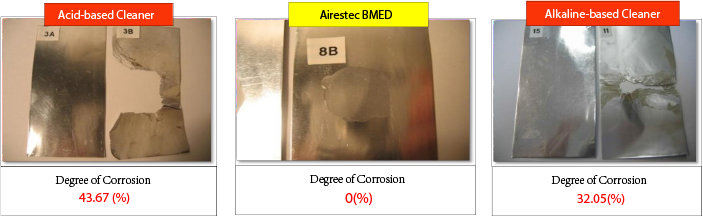

Most of the contractors use acid and alkaline based cleaner to clean the air-conditioning cooling coil. As a matter of fact, these cleaners are very corrosive in nature (Refer figure 1). Constant use of acid/alkaline cleaner could damage cooling coil to certain extent and compromise the heat transfer. As a result, energy efficiency of the system would reduce and energy bill would go up !

Figure 1: Degree of corrosion among acid, alkaline, and Airestec BMED

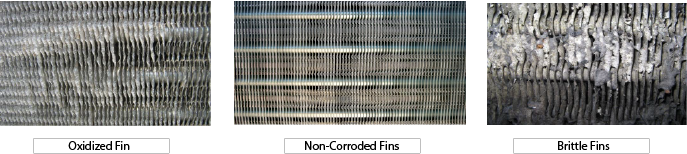

Figure 2: Effect of acid/alkaline based cleaner on cooling coil (left & right) v.s. Airestec BMED (middle)

HOW ARE WE DIFFERENT FROM OTHERS ?

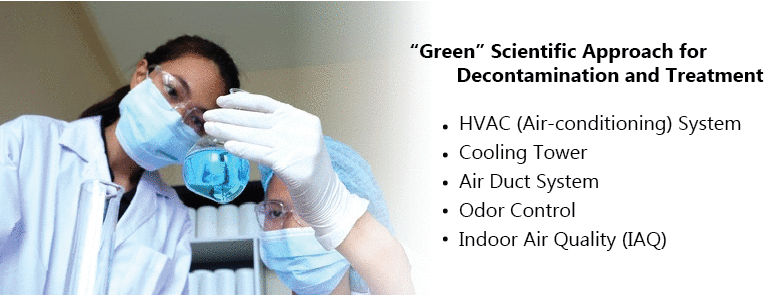

We have more than 20 years’ of experiences in decontamination and treatment of Heating, Ventilating, Air Conditioning, and Refrigeration (HVAC) system using proprietary enzyme technology. Our proprietary green, eco-friendly, bio-based scientific solution for decontamination and treatment can offer clients series of benefits:

- Reduce energy consumption

- Maintain system efficiency

- Reduce operating cost

- Prolong equipment lifespan

- Protect assets and equipment

- Improved indoor air quality (IAQ)

- Protect Human Health

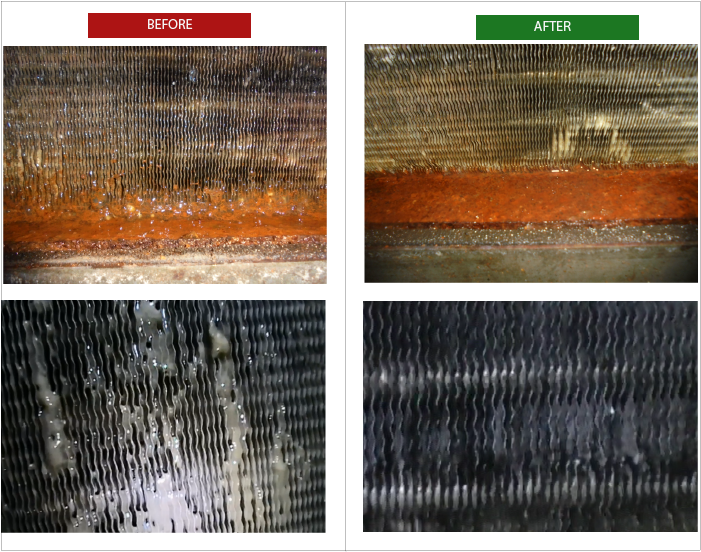

Our proprietary enzymatic air-cond coil cleaner, named BMED, is a safe, neutral (pH 7), and environmentally friendly product that is specially designed to break down biofilm and clean the coil without damaging the surface structure (refer figure 2). Biofilm is referred to a group of microorganism that attaches to a surface. Biofilm would secrete organic acids along proliferation and development, which causes localized corrosion on coiling coil. Corrosion caused by biofilm is irreversible. Nevertheless, Airestec treatment service can retard the growth of microorganism and biofilm on cooling coil with a 12-month warranty (refer figure 4). Absence of biofilm can reduce the corrosion rate to minimum.

We strictly adhere to Standard Operating Procedure (SOP) for every service to deliver highest standard quality of work and ensure customer satisfaction. In fact, our technicians are well-trained and certified with necessary qualifications.

Figure 3: Condition of cooling coil before and after decontamination using Airestec BMED

Figure 4: Airestec coil treatment can prevent and delay the growth of microorganism on cooling coil